Cleaning Comes with Choices

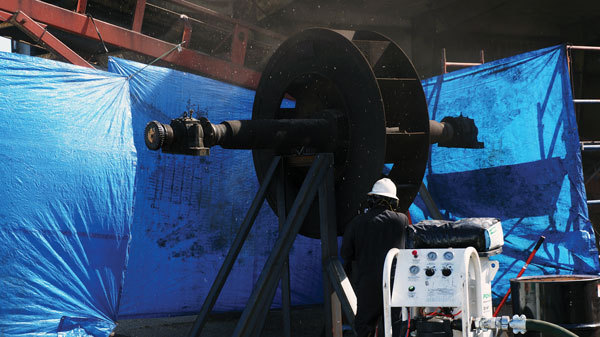

PHOTO: SPONGE-JET

May 18, 2017

BY Mark Parenteau

Advertisement

Advertisement

Related Stories

U.S. fuel ethanol production was down 7% the week ending April 12, according to data released by the U.S. Energy Information Administration on April 17. Stocks of fuel ethanol were down slightly and exports expanded by more than 12%.

A record volume of sugarcane was processed during Brazil’s recently completed 2023-’24 harvest season, according to UNICA, the Brazilian sugarcane industry association. Ethanol production also set a new record, with a significant boost from corn.

Marquis and United Cooperative on April 16 announced the sale of Marquis’ 100 MMgy Necedah, Wisconsin, ethanol facility to United Cooperative. The facility will operate under the new name of United Energy Necedah LLC.

Carbogenesis, a global private equity fund focused on industrial decarbonization, and Octent Automation, which provides tools designed to enhance outcomes during the fermentation process, have joined the RFA as associate members.

Sustainable Aviation Buyers Alliance has announced the largest ever collection of deals to purchase high-integrity SAF certificates (SAFc), with SABA members committed to channel close to $200 million into purchasing SAFc over five years.