Latest News

17 hours ago

By Erin Voegele

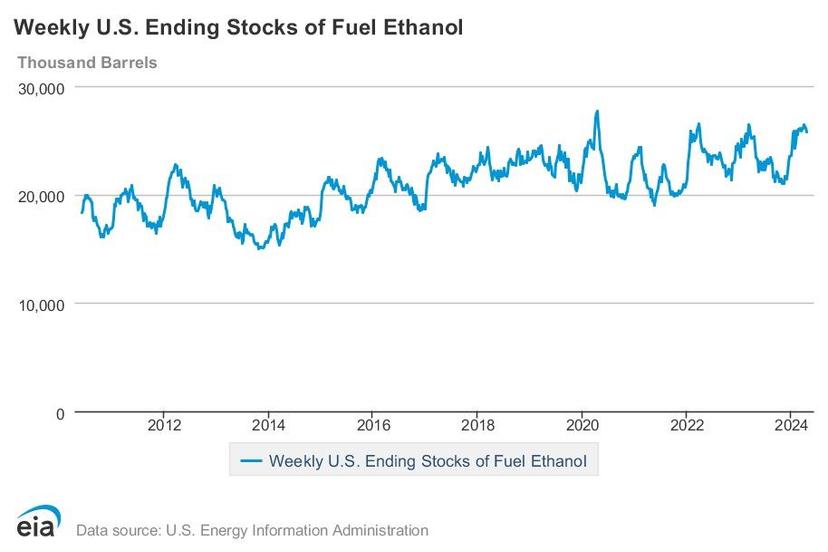

U.S. fuel ethanol production expanded by more than 3% the week ending April 26, according to data released by the U.S. Energy Information Administration on May 1. Stocks of fuel ethanol were down 1% and exports were down 42%.

Read More

U.S. Senate Agriculture, Nutrition and Forestry Committee Chairwoman Debbie Stabenow, D-Mich., and House Agriculture Chairman Glenn “GT” Thomspon, R-Pa., on May 1 released outlines for competing versions of the 2024 Farm Bill.

Total U.S. biofuels operable production capacity fell slightly in February, according to data released by the U.S. Energy Information Administration on April 30. Feedstock consumption was up when compared to both the previous month and February 2023.

The Treasury Department and IRS on April 30 released new guidance on the SAF tax credit and announced the launch of the 40BSAF-GREET 2024 model, which incorporates a pilot-program to encourage the use of climate-smart ag practices for SAF feedstocks.

Archer Daniels Midland Co. on April 30 released first quarter financial results, reporting improved earnings for Vantage Corn Processors subsegment, which includes the company’s dry mill ethanol plants.

Featured Articles

By creating optimal conditions to maximize corn oil output, Fluid Quip Technologies’ pretreatment system gives ethanol producers an unfussy method to maximize production.

Lee Reeve, a multi-generational Kansan who operates a feedlot colocated with a small ethanol plant, explains how producing fuel and feed has impacted his family business for over four decades.

The U.S. Department of the Treasury’s late 2023 guidance on carbon-intensity modeling is a potential step in the right direction for ethanol becoming a major feedstock for SAF. But many questions remain.

The life cycle analysis of GHG emissions is essential in a world full of credits and customer requirements revolving around carbon intensity. Life Cycle Associates knows how to help ethanol producers square it all up to maximize value.

Upcoming Events

Podcasts

April 2024

EPM's Podcast Series Energy-efficient Oil Recovery and USDA Grant Opportunities: A Conversation with ICM and Christianson PLLP

S3 E2 This month's Ethanol Producer Magazine podcast features, Alex Wayman, ICM and Jamey Cline, Christianson PLLP View More.

Current Job Postings

EH&S Manager

POSTED BY: Ring-neck Energy & Feed, LLC

The EH&S Manager is responsible for implementing systems to meet environmental, health and safety regulations, and performance for the facility.

ESSENTIAL FUNCTIONS AND BASIC DUTIES

- Implement facility’s Emergency Action Plan (EAP), Integrated Contingency Plan (ICP), Spill Prevention, Control and Countermeasures (SPCC), Risk Management Plan (RMP), and Storm Water Pollution Prevention Plan (SWPPP).

- Assist the facility’s commitments under the sites Air, Appropriations, NPDES, and Waste permits. Complete multi-media responsibility for task driven commitments.

- Establish and maintain relationship with Local Emergency Planning Committee (LEPC) and response organizations to facilitate their participation with facilities response planning.

- Responsible for building and ensuring implementation of a strong ProcessSafety Management (PSM) program. Support compliance with Risk Management Planning (RPM) and reporting to the Environmental Protection Agency (EPA).

- Provide comprehensive and effective EHS training. Design and implement new training programs to address gaps. Ensure implementation of Safe Work Practices (SWP) and create written health and safety procedures and programs to meet OSHA, PSM, FRA, and other applicable regulatory standards.

- Investigate incidents for facility using investigative methodologies, and drive preventive action items to completion using tracking methods.

- Implement tasks defined on Environmental Health and Safety routine duties calendar, ensuring 100% compliance, including incident reports and follow up actions to prevent recurrence.

- Assist with and support proper management of SDS documents and PPE hazard assessments, per OSHA regulations.

- Conduct internal audits on the facility and support external audits to ensure continual improvement of processes and programs.

- Ensure day to day environmental and safety compliance requirements and support facility with safety compliance during shutdown activities.

- Communicate any compliance issues to the Plant Manager and assist in developing correction action plans.

- Track leading and lagging indicators for health and safety performance.

- Assist with new hire onboarding and drug screen testing, support the industrial hygiene programs, and prepare reports.

Maintenance Technician

POSTED BY: Ring-neck Energy & Feed, LLC

POSITION PURPOSE Responsible for the repair and maintenance of the plant equipment to ensure maximum production quantity and quality, while supporting the policies, goals, and objectives of the company. ESSENTIAL FUNCTIONS AND BASIC DUTIES • Repair or replace plant equipment or systems on a scheduled or emergency basis. • Perform preventative maintenance activities as required. • Communicate directly with production and shipping/receiving department to coordinate maintenance and repair work. • Assist with diagnosing and trouble-shooting maintenance related issues. • Assist with new installations and other projects, as requested by supervisor. • Work with engineer and external contractors to plan and implement installation of new equipment or systems. • Participate and follow all safety, health, and environmental programs. • Know and understand city, county, state, and federal regulations relating to maintenance and plant equipment, and work in a manner to ensure that these regulations are met at all times. • Work in a safe manner at all times. • Participate in programs and procedures required to ensure plant cleanliness. • Be available for overtime work on a scheduled or call-in basis as required. • Know and understand basic machines and tools, including their designs, uses, repair, and maintenance. PHYSICAL ACTIVITIES AND REQUIREMENTS OF THIS POSITION The majority of time will be spent in the plant. All types of chemical industry equipment are used in the plant to include, but not limited to fermentation vessels, jet cookers, agitators, mixing and milling equipment, distillation columns, centrifuges and distributive control systems. May be exposed to loud noises, wet and humid conditions, fumes or airborne particles, toxic chemicals, extreme hot and cold depending on weather conditions. Must be able to climb ladders and work at elevations of 175 feet. Must be able to speak and listen clearly. Fine visual acuity to read for accuracy. Travel required or as needed. For more detail please review the ADA questionnaire on file in Human Resources. PHYSICAL STRENGTH: This job may require lifting of up to 50 pounds occasionally. INTENT AND FUNCTION OF JOB DESCRIPTIONS All descriptions have been reviewed to ensure that only essential functions and basic duties have been included. Peripheral tasks, only incidentally related to each position, have been excluded. Requirements, skills, and abilities included have been determined to be the minimal standards required to successfully perform the positions. In no instance, however, should the duties, responsibilities, and requirements delineated be interpreted as all-inclusive. Additional functions and requirements may be assigned by supervisors as deemed appropriate. In accordance with the Americans with Disabilities Act, it is possible that requirements may be modified to reasonably accommodate disabled individuals. However, no accommodations will be made which may pose serious health or safety risks to the employee or others or which impose undue hardships on the organization. Job descriptions are not intended as and do not create employment contracts. The organization maintains its status as an at-will employer. Employees can be terminated for any reason not prohibited by law.

Process Operator

POSTED BY: Heron Lake BioEnergy, LLC