Appetite for Improvement

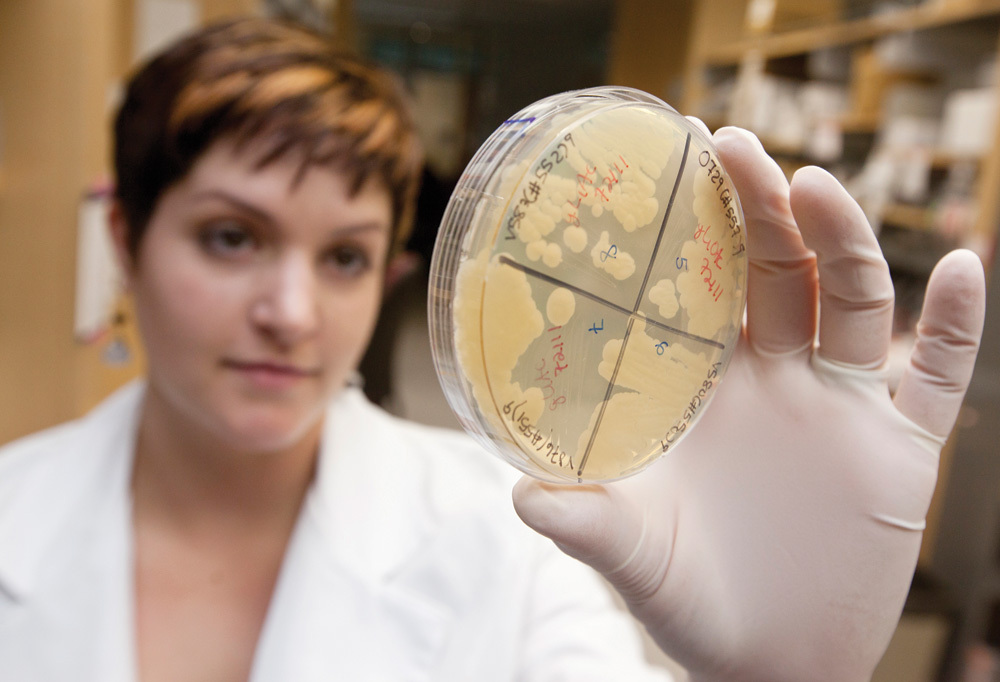

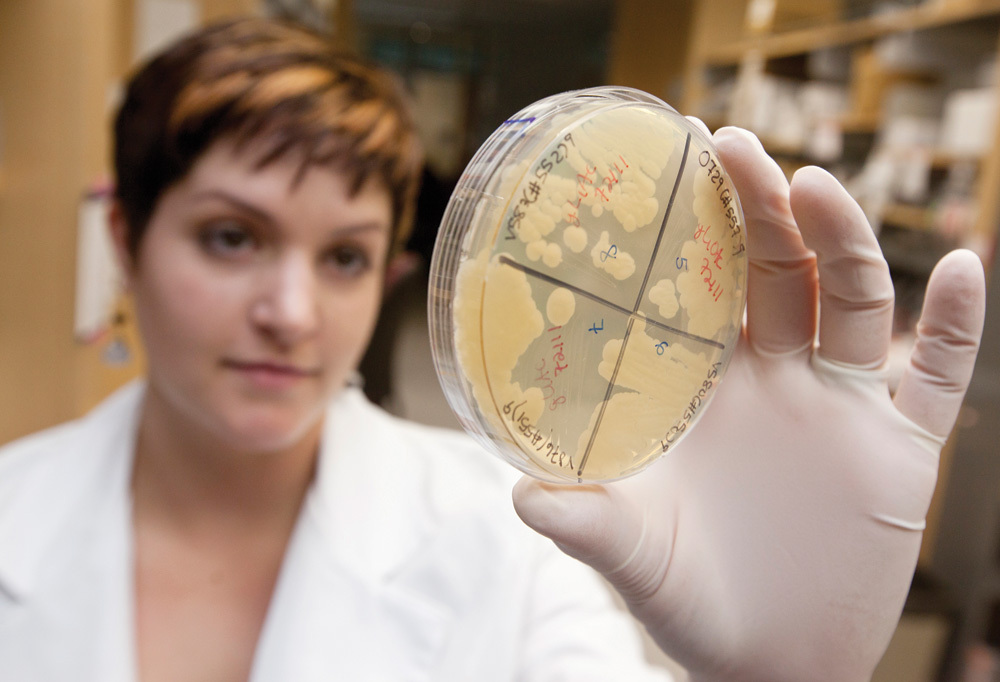

PHOTO: MATTHEW WISNIEWSKI, U.S. DOE GREAT LAKES BIOENERGY RESEARCH CENTER

August 15, 2011

BY Kris Bevill

Advertisement

Advertisement

PHOTO: MATTHEW WISNIEWSKI, U.S. DOE GREAT LAKES BIOENERGY RESEARCH CENTER

August 15, 2011

BY Kris Bevill

Advertisement

Advertisement