February 2008

View Full Print Edition

View Full Print EditionBusiness Briefs

A Different Path to Biodiesel

By Jerry W. Kram

Columns

The Way I See It

By Mike Bryan

Understanding Restrictions on Transfers of Membership Units

By Shannon M. Bielski

For the Sake of Full Disclosure …

By Tom Bryan

The Energy Bill's Details, Impact: TBD

By Tom Bryan

Featured

Strategic Planning for Ethanol Plant Boards

By Jesse McCurry

Renewable fuels got the best holiday gift ever in December—an Energy Bill with an unprecedented 36 billion gallon renewable fuels standard. Right after it was signed, EPM talked with a number of corn-ethanol producers and those advocating cellulosics to gauge their reactions.

Traversing the Waterways

By Bryan Sims

The convergence of the marine transport sector and the ethanol industry is relatively new. EPM talks with maritime trade experts to see if the shipping industry can keep up with growing demand from the ethanol industry.

Constructing Economics

By Craig A. Johnson

The bottom line is a big concern for those in the ethanol industry today. EPM takes a detailed look at what's changed on the construction side of the equation in the past year that could impact the industry in the coming year.

Familiar Face Takes the CRFA Helm

By Dave Nilles

Following the departure of longtime Executive Director Kory Teneycke the Canadian Renewable Fuels Association looked for government experience for his replacement. New CRFA President Gordon Quaiattini has taken the lead and is providing the Canadian biofuels industries with an experienced voice.

Ethanol in the Fast Lane

By Ron Kotrba

Oil companies and distributors in the Southeast are taking advantage of sustained lower ethanol prices, which has led to a rather interesting series of events.

In Search Of Biomass Storage Solutions

By Jerry W. Kram

When it comes down to the best way to move biomass from the field to the factory, the dry look may be out. Wet biomass offers advantages that may send the big bale back to the ranch to feed cattle.

Move Over Corn, Wheat's King In Western Canada

By Susanne Retka Schill

Western Canadian wheat growers anticipate ethanol will energize the wheat market there in the same way it has the U.S. corn market by creating a new use for the dominant grain crop. Using wheat to produce ethanol, however, has its challenges.

Going Beyond the Corn Kernel

By Michael Shirek

Poet LLC didn't have far to travel to find a feedstock that it can use to turn the corner on cellulosic ethanol. During the 2007 corn harvest, the company showcased its plans to use corncobs as the primary feedstock for Project Liberty, its cellulose-to-ethanol expansion project at Poet Biorefining Emmetsburg in Iowa.

Costly Chemicals

By Jessica Ebert

The once abundant and relatively cheap chemicals indispensable for the production of ethanol are now hard to get and expensive. Although the rapid rise of the industry is partly to blame for this, other factors are influencing the increasing cost of these compounds including high natural gas prices, the demands of the metal industry and incresing demand for fertilizer.

How Big is Commercial Scale?

By Ron Kotrba

How big is a commercial-scale cellulosic ethanol plant, and will we know it when we see it?

Quick Off the Straw

By Tom Bryan

A team of amateur race car drivers made history in December, powering a pair of Le Mans prototype race cars on cellulose-based E85 in the world's longest road race.

WIREC 2008: A Global Perspective on Renewable Energy

By Sarah Smith

Thousands of world and business leaders, legislators, global energy gurus and policy wonks are expected to converge on Washington, D.C., March 4-6 for what is being billed as the "largest all renewable energy event in U.S. history."

All Roads Lead to Rome and Rice

By Ron Kotrba

Executives with Colusa Biomass Energy Corp., a company securing its niche in rice waste, were searching diligently for an engineering company to take their project to the next level: commercial production. No matter the paths they traversed, CBEC execs say all roads led to BBI International.

Cool, Hot and Green

By Susanne Retka Schill

District Energy St. Paul Inc. relies predominantly on biomass power to heat and cool the majority of downtown St. Paul, Minn. The goal is to replace all fossil fuels in the future.

Lukewarm on Cofiring

By Anduin Kirkbride McElroy

Cofiring biomass in coal-powered plants is a way to include renewable energy within the existing grid. Can renewable mandates regulations encourage utilities to utilize biomass, and is it a good idea?

Agricultural Versus Industrial Waste for Energy

By Jessica Ebert

Feedstock availability, consistency and the hype surrounding alternative fuels are all challenges to the development of waste-to-energy projects.

Straw Tiger

By Marianne Osterkorn

Chinese farmers could earn more money by cutting their country's coal consumption. Straw residues from agricultural production are becoming an appealing feedstock for cofiring in power plants.

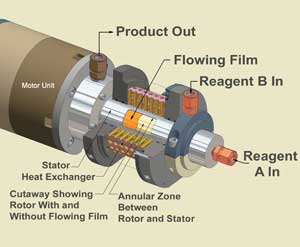

Putting the Squeeze on Convention

By Ron Kotrba

Biodiesel Magazine talks with a California-based company about its unique reactor design and unconventional business plan that will lead to the construction of a model refinery on the East Coast.

Making Pennycress Pay Off

By Susanne Retka Schill

Pennycress is a weed that researchers think has the potential to quell the food versus fuel debate. If initial findings prove true, it could become a biodiesel feedstock that doesn't compete with corn and soybeans for acres.

A Billion-Gallon Boost

By Dave Nilles

The biodiesel industry claimed several important victories in the latest Energy Bill. Fuel labeling, performance studies and an all-important specific carve-out are expected to enhance production and market confidence. However, critical issues remain as the dust settles.

No Need to Splash

By Jerry W. Kram

Biodiesel doesn't typically go straight from the processor to the fuel tank. It has to be distributed, blended and then redistributed to retailers before it's sold to consumers. Managing the transfers and tracking the blending is important to growing a viable biodiesel industry.

Probing Soybean Physiology

By Jessica Ebert

On the surface it seems simple: too little water or too high temperatures during the growing season equals disappointing soybean yields. A closer look, however, reveals a host of entwined physiological changes in the soybean seed that result in this deflating outcome. Soybean physiologists spoke with Biodiesel Magazine about how they're trying to understand these changes in an attempt to improve yields.

Moving Biodiesel

By Anduin Kirkbride McElroy

Distribution of fuel makes up less than 10 percent of the cost of biodiesel, but there's a lot of flux within that 10 percent. Trucks, trains and barges each offer options to control costs and reach markets.

A Southern Transformation

By Bryan Sims

Tennessee Gov. Phil Bredesen's bold leadership has unlocked the state's potential to become a biodiesel producer and user.

Do-it-Yourself Oil Extraction

By Jerry W. Kram

The conventional wisdom has always been that combining oil crushing and biodiesel production is too expensive for all but the largest producers. That thinking has put biodiesel producers at the mercy of a volatile and capricious oil market. A California engineering firm says it's found a way for biodiesel makers to take control of their feedstocks.

From Concept to Commercialization

By Jerry W. Kram

Figuring out how to make fuel and chemicals from biomass is only the first step, making those processes economically viable is the ultimate goal. Researchers at the National Renewable Energy Laboratory in Colorado work with large and small businesses to turn their discoveries into commercial successes.

Contributions

The Endangered Species Act's Hidden Costs for Ethanol Production

By Francis E. Chin

The Changing Ethanol Environment

By Rick Kment

The Hidden Costs of the Renewable Fuels Standard

By Clayton McMartin

Recalibrating the Board of Directors

By Tracy E. Houston and Cindy Knutson

Managing Leadership Stress

By Patrick B. Ropella

Biomass Gasification: Any New Environmental Concerns?

By Todd A. Potas