November 2008

View Full Print Edition

View Full Print EditionBusiness Briefs

Columns

Risk Management Committees Hedge With Best Practices

By Judd W. Vande Voort

Weather, Economics Affect Projects

By Bryan Sims

Is the Tide Changing?

By Robert Vierhout

New Coal

By Art Wiselogel

Politics and Biomass

By Rona Johnson

Safety Should Truly Come First

By Jessica Sobolik

Sustainability is Key for Biodiesel Industry

By Kelly King

Featured

Making The Switch

By Susanne Retka Schill

The commercial production of cellulosic ethanol will require thousands of tons of biomass. EPM details three programs designed to entice farmers to switch from corn and soybeans to energy crops.

On Target for 2012

By Ryan C. Christiansen

The National Renewable Energy Laboratory must help the United States to develop the technology necessary for making cheap fuels from cellulosic biomass by 2012. It's a goal that's not negotiable.

Second-Generation Enzyme Logistics

By Ron Kotrba

EPM talks with three major enzyme makers about the challenges that lie ahead to cost-effectively manufacture and distribute cellulase and hemicellulase enzymes for biomass-based ethanol production.

Furfural: Future Feedstock for Fuels and Chemicals

By Jessica Ebert

Furfural, a sister chemical to the increasingly popular hydroxymethylfurfural or HMF molecule, is regaining attention as a biobased alternative for the production of everything from cellulosic ethanol and fertilizers to plastics and paints.

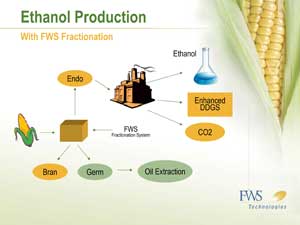

Is Fractionation the Cure for High Corn Prices?

By Amanda Watkins

In the wake of recent price hikes in the corn market and rising global food costs, ethanol producers are looking for ways to cut operating costs. One option that is starting to gain traction is fractionation. While the process isn't new, it is becoming an attractive option for ethanol producers who are feeling the financial pinch of this turbulent year.

Fueling a Revolution

By Anna Austin and Erin Voegele

The theme and tenor of the American Coalition for Ethanol's 21st Ethanol Conference & Trade Show clearly signaled that the industry is determined to overcome challenging economic conditions, negative press and misinformation that has plagued the industry.

Clearing the Air

By Kris Bevill

Prudent ethanol producers have shown an interest in becoming generators of carbon credits and are leading the way for others to follow despite the fact that carbon trading the United State is done on a voluntary basis. This is the first of EPM's two-part look at the current U.S. market and what might be in store for 2009.

Cruisin' on E85

By Hope Deutscher

Craig Ammann of KL Process Design Group and a South Dakota Harley-Davidson dealership converted Ammann's 2004 Electra Glide Harley-Davidson motorcycle to run on ethanol.

Betting on Biobricks

By Suzanne H. Schmidt

Tom Engel traveled halfway across the world in search of a way to make clean, dependable, renewable energy and brought back BioBricks. With these compact, environmentally friendly, biomass-based briquettes he aims to ease the pain that people experience when paying their heating bills.

Plastics From the Prairie

By Jerry W. Kram

Whether red, green or blue, tractors are as indispensable to a farmer as seed or land. Someday, parts of those tractors may be made from last year's harvest as researchers from North Dakota State University seek ways to make reinforced composite plastics from the oils, proteins and fibers grown in American fields.

Proving Out Plasma Gasification

By Bryan Sims

Researchers believe that the economics are right for using plasma gasification technology to convert municipal solid waste into energy. It's just a matter of getting that first commercial plant built in the United States for it to catch on.

Acid Trip

By Ron Kotrba

Biorefineries built on the biochemical conversion platform can take advantage of their fermentative capacity to produce various organic acids, which can then be reacted with ethanol to make a number of different higher-valued ester compounds.

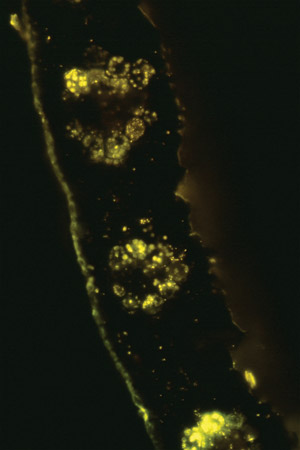

Switchgrass: A Bioplastic Factory

By Jessica Ebert

In the past, cheap oil spurred the development of petroleum-based consumer products such as plastics. Today high oil prices are driving research and development away from fossil fuel-based processes to those using renewable feedstocks. The markets for these new bioproducts are growing and companies such as Massachusetts-based Metabolix Inc. are cashing in by engineering bioenergy crops that also serve as factories for bioplastics.

Oilseed Comes of Age

By Susanne Retka Schill

Camelina has yet to make the scene as a biodiesel feedstock, thanks partly to high commodity prices that dampened farmers' interest in trying the new crop. Enough has been raised to test its biodiesel performance and promoters still praise its potential.

The Truth Behind the Claims

By Erin Krueger

Is jatropha a wonder crop that can transform the biodiesel industry and provide a quick and easy income for farmers? Although many of these claims are true, numerous challenges must be overcome before large-scale production of the biodiesel feedstock can begin. Jatropha holds a great deal of potential, but only if it's properly developed, which may take years.

Algae Interests Align

By Jerry W. Kram

After decades of study and millions of dollars in investments, using algae as a feedstock for alternative fuels seems tantalizingly close. However, several hurdles remain, prompting the cooperation of those interested in the economical development of algae oil as a biodiesel feedstock.

The Skinny on Fats

By Ron Kotrba

The North American rendering industry takes anything that isn't used for food from the animal carcass-all 60 billion pounds-and recycles it into everything from animal feed to biodiesel feedstock. Here's an overview of North American rendering and biodiesel from animal fats.

A Greasy Alternative

By Kris Bevill

One of the most popular feedstocks being used by biodiesel producers today is yellow grease. Biodiesel Magazine examines the logistics of using waste cooking oil.

Continued Strength in Oil Prices

By Ryan C. Christiansen

Around the world, the forecast for biodiesel feedstock prices is more of the same as consumption threatens to outpace production.

Sustainability is Key for Biodiesel Industry

By Kelly King

Contributions

A Guide to Successful Yeast Propagation

By Patrick Heist

Emerging Energy Optimization Opportunities for Ethanol Facilities

By Philip A. Marrone, Kenneth R. Liberty and David J.

Cellulosic Ethanol Collaborations: Matchmaking Isn't Easy

By Carey Jordan and Paul Landen

The Important Role of Enzymes in Cellulosic Ethanol

By Emmanuel Petiot

Tighter Markets Provide Opportunities, Challenges

By Todd Taylor